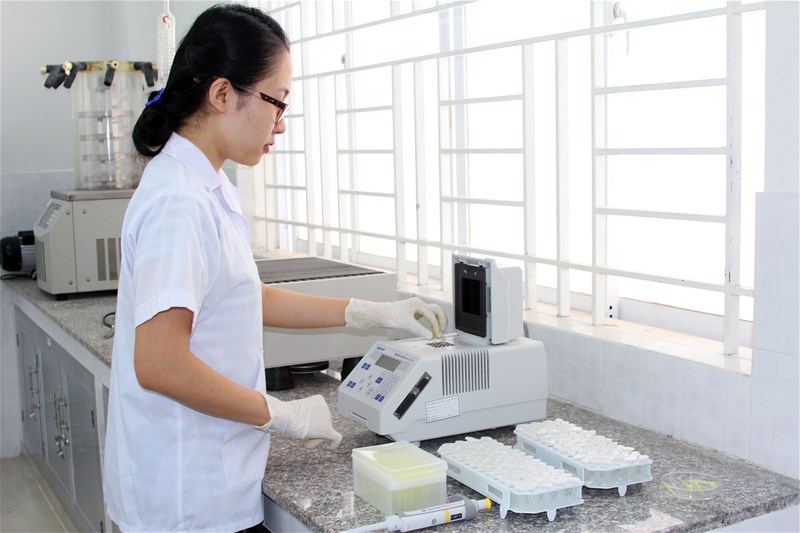

Conditions on infrastructure for accreditation of GMO laboratories in Vietnam

On November 20, 2012, the Ministry of Science and Technology of Vietnam issued the Circular No. 20/2012/TT-BKHCN providing detailed guidance on conditions and procedures for accreditation of genetically modified organisms laboratories.

According to Article 7 of the Circular No. 20/2012/TT-BKHCN of the Ministry of Science and Technology of Vietnam, conditions on infrastructure for accreditation of GMO laboratories (genetically modified organisms) are specified as follows:

* General conditions:

- A GMO laboratory is divided into work area and auxiliary area (if necessary) according to their activities;

- A GMO laboratory shall be isolated from external environment and different research subjects are isolated from each other;

- A GMO laboratory shall have electric system (having backup power source), water system, fire protection system; washing area; hand-wash sink and eye- wash stations;

- The systems for specimen treatment and cleaning of experiment equipment, waste, waste-water and destruction of waste materials shall comply with regulations;

- Personal protective equipment shall be sufficient and appropriate for the level of biosafety;

- The perimeters of the work area and auxiliary area shall be established and marked with signs using P2-KTNC and P3-KPT forms prescribed in Appendix I issued together with this Circular;

- Ventilation, air-conditioning and humidity regulation systems shall be adequate for research activities.

* The work area:

- Conditions to be satisfied by a biosafety level 1 laboratory: The minimum area is 20 square meters; the grounds, walls, ceilings and doors are smooth, easy to clean, waterproof, fireproof and hard to break. Work tables are made of heatproof, corrosion-resistant and impact-resistant materials. Research equipment is adequate. The work area is divided into 3 sectors (preparation sector, treatment sector and work sector) to which the equipment is distributed in a manner that facilitates the work and safety management.

- Conditions to be satisfied by a biosafety level 2 laboratory: The minimum area is 30 square meters. The biosafety level 2 laboratory shall comply with other conditions prescribed in Point a Clause 2 of Article 7 of this Circular. In addition, the work sector shall be separated from other sectors and have doors and locks.

- Conditions to be satisfied by a biosafety level 3 laboratory: The minimum area is 40 square meters. The biosafety level 3 laboratory shall comply with other conditions prescribed in Point a Clause 2 of Article 7 of this Circular. The liquid waste is treated by a system that meets the national environment standards before being discharged into the common treatment sewage system. Work sector is divided into 02 separating rooms: anteroom and workroom. These rooms must have an automatic door system that only allows either anteroom’s door or workroom’s door to be opened at a time to make sure that the workroom is always isolated from outside. These rooms must have a one-way air filter system to make sure that the anteroom's pressure is lower than outside pressure and higher than the workroom’s pressure. In addition, these rooms must have telephones and alarm bells.

- Conditions to be satisfied by a biosafety level 4 laboratory: The minimum area is 50 square meters. The biosafety level 4 laboratory shall comply with other conditions prescribed in Point c Clause 2 Article 7 of this Circular. The biosafety level 4 laboratory shall have bathrooms and locker-rooms between the anteroom and workroom and an independent air provider system in case of necessary.

* The auxiliary area:

- The auxiliary area has net houses, greenhouses, ponds, cages, drying places, slaughterhouses, storage of raw materials, feed, storage of products and waste treatment area in order to serve the activities written in the Certificate;

- The auxiliary area layout is suitable for each research subject and makes sure that GMOs are isolated from surrounding environment and effects of surrounding environment.

View more details at the Circular No. 20/2012/TT-BKHCN of the Ministry of Science and Technology of Vietnam, effective from January 04, 2013.

Le Vy

- Key word:

- Circular No. 20/2012/TT-BKHCN

- Statute of limitations for administrative sanctions in the field of insurance business in Vietnam from February 15, 2025

- 06 solutions for implementing the proposal to build and manage the National Information and Database System on Planning in Vietnam

- Approval of the National Action Plan on infection control in healthcare facilities for the 2025-2030 period in Vietnam

- Professional qualifications in the production, trade, and use of industrial explosives in Vietnam

- New regulations on notarization database in Vietnam from July 1, 2025

- Ministry of Construction of Vietnam issues administrative reform plan for the year 2025

-

- Vietnam: Inspection of application for accreditation ...

- 16:35, 05/01/2013

-

- Application for accreditation of GMO laboratories ...

- 16:30, 05/01/2013

-

- Detailed regulations of operation of GMO laboratories ...

- 16:22, 05/01/2013

-

- Vietnam: Periodic maintenance of equipment in ...

- 16:20, 05/01/2013

-

- Vietnam: A GMO laboratory shall have at least ...

- 16:03, 05/01/2013

-

- Statute of limitations for administrative sanctions ...

- 08:30, 07/01/2025

-

- Procedures for inspection and issuance of Certificate ...

- 08:00, 07/01/2025

-

- Approval of the National Action Plan on infection ...

- 16:30, 06/01/2025

-

- Professional qualifications in the production ...

- 15:54, 06/01/2025

-

- Regulations on the color of priority signal lights ...

- 15:00, 06/01/2025

Article table of contents

Article table of contents