What is Vietnam Standard TCVN 1916: 1995 on Bolts, screws, studs, and nuts about? What are the technical requirements for Bolts, screws, studs, and nuts?

- What is Vietnam Standard TCVN 1916: 1995 on Bolts, screws, studs, and nuts about?

- What are the instructions for labeling Bolts, screws, studs, and nuts according to Vietnam Standard TCVN 1916: 1995?

- What are the regulations on the testing method for Bolts, screws, studs, and nuts under Vietnam Standard TCVN 1916: 1995?

What is Vietnam Standard TCVN 1916: 1995 on Bolts, screws, studs, and nuts about?

Vietnam Standard TCVN 1916: 1995 on Bolts, screws, studs, and nuts - Technical requirements announced in Decision 2844/QD-BKHCN in 2008 announcing national standards issued by the Minister of Science and Technology.

Vietnam Standard TCVN 1916: 1995 applies to Bolts, screws, studs and nuts, with metric threads according to TCVN 2248 - 77 with thread diameters from 1 to 48 mm

Technical requirements according to Vietnam Standard TCVN 1916: 1995 for external form, mechanical properties, and materials are as follows:

Texture, dimensions, surface roughness, thread tolerances and dimensional tolerances, shape tolerances, and surface positions are specified in the standards for specific products

External form

- The surface of Bolts, screws, studs, and nuts must be smooth, without scratches or oxygen flakes.

- Permissible defects of the surface of Bolts, screws, and studs according to TCVN 4795 -89.

- Permissible defects of nut surfaces according to TCVN 4796 - 89.

Mechanical properties and materials

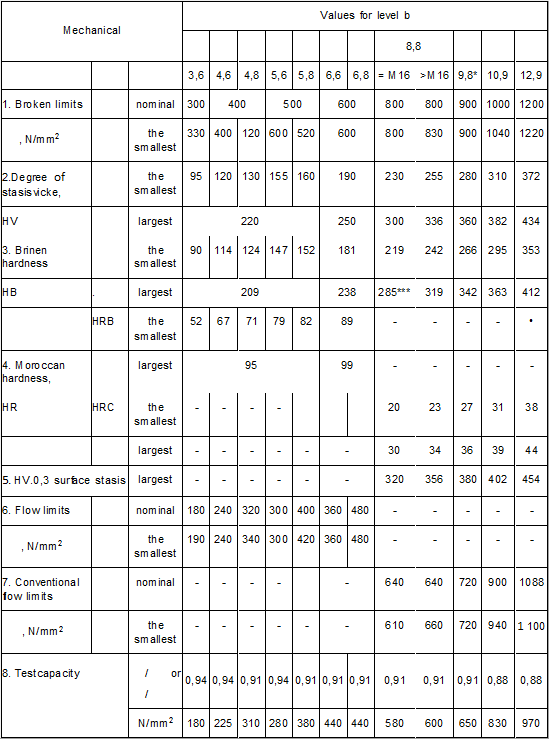

- The mechanical properties of bolts, screws (excluding positioning screws), and studs from alloy steels and steels must usually follow the instructions in Table 1

See detailed table 1 (Mechanical properties of bolts, screws, and studs) in Vietnam Standard TCVN 1916: 1995

- Mechanical properties of positioning screws and similar clamping elements working without pulling from ordinary steel and alloy steel according to TCVN 4674 - 89.

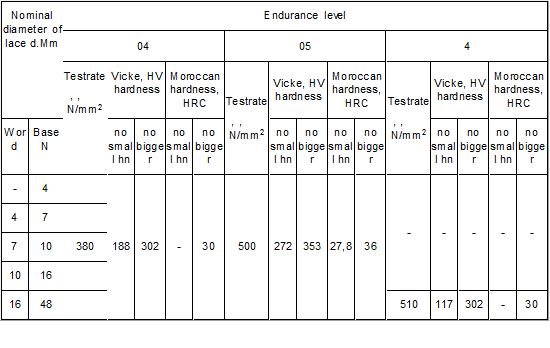

- Mechanical properties of nuts from ordinary steel and alloy steel as indicated in Table 2.

See detailed table 2 (Mechanical properties of nuts) in Vietnam Standard TCVN 1916: 1995

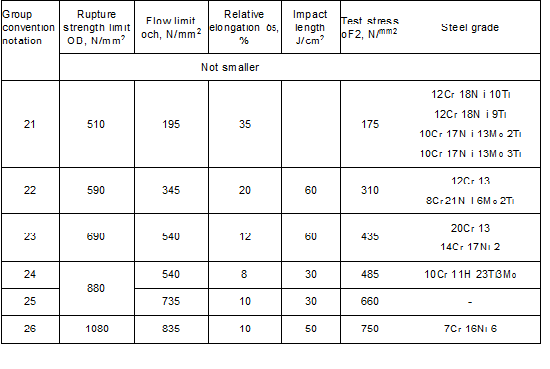

- Mechanical properties of Bolts, screws, studs, and nuts from wear-resistant steel, hot strength as indicated in tables 3 and 4.

- Mechanical properties of bolts, studs, and non-ferrous alloy nuts as indicated in tables 5 and 6.

See details of tables 4 - 6 in Vietnam Standard TCVN 1916: 1995

- It is permissible to make Bolts, screws, studs and nuts from metal and alloy grades not specified in tables 3 – 6. At that time, their mechanical properties should not be lower than the specified values for the corresponding groups.

- According to customer requirements, clamping parts from brass, fabricated by cold burial, must be heat treated to reduce internal stress.

What are the instructions for labeling Bolts, screws, studs, and nuts according to Vietnam Standard TCVN 1916: 1995?

Under the provisions of subsection 2.6 Section 2 of Vietnam Standard TCVN 1916: 1995, the labeling is shown as follows:

General requirements

- Six-bladed head bolts, cylindrical head screws with submerged 6-sided holes for installing screw keys, studs and six-sided nuts need to be marked with the strength class symbol and material group, the mark of the manufacturing facility; For the left lace detail, it is necessary to add the left lace symbol.

- Products not specified in Article 2.4.1.1 of Vietnam Standard TCVN 1916: 1995 and not specified durability class are labeled as agreed with customers

- The label can be floating or submerged

The label size is determined by the manufacturer

- Labeling six-sided head bolts and six-sided hole cylindrical head screws for installing screw keys

- Labeling is carried out for bolts and screws with a thread diameter of ≥ 6mm.

- The label is indicated on the foam surface or side of the bolt or screw head. The label on the surface of the bolt head edge must be submerged.

- When embossed labeling, it is permissible to increase the maximum limit height of the bolt or screw head by one value:

0.1 mm – for threaded diameter parts | d ≤ 8mm; |

0.2 mm – for threaded diameter parts | 8mm < d ≤ 12mm; |

0.3mm – for threaded diameter parts | d ≥ 12mm |

Labeling of studs

- Labeling is carried out for studs with a threaded diameter of ≥ 12mm.

For studs with a thread diameter of ≥ 8mm, replacement markings are allowed:

O – for endurance class 8.8; |

+ - for durability class 9.8; |

- for endurance class 10.9; |

- for endurance class 12.9. |

- The label is indicated on the sucker of the stud head with a nut

Labeling of six-sided nuts

- Labeling is carried out for nuts with a thread diameter of ≥ 6mm.

- The label is written on one of the two suckers. Under technical conditions, labeling is allowed on the edge surface of the nut (Figure 2). The label must be impressed.

- Labeling is applied to the nut in the style of the watch dial. In this case, the label is embossed or sunk into the beveled edge or submerged on the button face

- Labeling of Bolts, screws, studs, and nuts with left threads shall comply with TCVN 212 – 93.

What are the regulations on the testing method for Bolts, screws, studs, and nuts under Vietnam Standard TCVN 1916: 1995?

Under the provisions of Section 3 of Vietnam Standard TCVN 1916: 1995:

3.1. Inspect the outer form of Bolts, screws, studs and nuts is conducted without the use of a magnifying tool.

3.2. Inspect surface defects of Bolts, screws, and studs according to TCVN 4795 – 89.

3.3. Inspect for surface defects of nuts according to TCVN 4796 – 89.

3.4. Inspect the size of Bolts, screws, studs and nuts according to prescribed standards and technical documents.

3.5. Surface roughness is inspected by comparison with standard samples of surface roughness.

There is no need to inspect the surface roughness of manufactured products by cold stamping and foam face roughening (except for positioning screws).

3.6. The threaded roughness of Bolts, screws, and studs is inspected at the surface of the threaded propine.

There is no need to inspect the roughness of the rolling thread and the roughness of the nut thread when the manufacturing technology condition has been guaranteed.

3.7. Methods for inspecting the quality and thickness of plating according to TCVN 4392 – 86.

3.8. The damage load of Bolts, screws, and studs is indicated in tables 9 and 10 of annex 2, test loads are only in tables 13 and 14 of annex D.

Testing methods are specified in specified standards and technical documents.

3.9. The test load of the nut is indicated in tables 11 and 12 of Appendix C.

Testing methods are specified in specified standards and technical documents.

3.10. When Bolts, screws, and studs are made by non-thermal cutting method, mechanical tests are allowed to be carried out on metal samples of the same grade as the above product and conducted according to table 8.

Thus, the testing method for Bolts, screws, studs and nuts is carried out according to the above guidance of Vietnam Standard TCVN 1916: 1995.

LawNet