What are the details on the Vietnam Standard TCVN 7626: 2019 (ISO/IEC 15416: 2016)? What is the scope of application of Vietnam Standard TCVN 7626: 2019 (ISO/IEC 15416: 2016)?

- What are the details on the Vietnam Standard TCVN 7626: 2019 (ISO/IEC 15416: 2016)? What is the scope of application of Vietnam Standard TCVN 7626: 2019 (ISO/IEC 15416: 2016)?

- What are the abbreviated letters and symbols in Vietnam Standard TCVN 7626:2019?

- What are the general requirements for the measurement method according to Vietnam Standard TCVN 7626:2019?

What are the details on the Vietnam Standard TCVN 7626: 2019 (ISO/IEC 15416: 2016)? What is the scope of application of Vietnam Standard TCVN 7626: 2019 (ISO/IEC 15416: 2016)?

Vietnam Standard TCVN 7626: 2019 (ISO/IEC 15416: 2016) on Automatic identification and data capture techniques - Bar code print quality test specification - Linear symbols (abbreviated TCVN 7626: 2019) replaces TCVN 7626: 2008.

Vietnam Standard TCVN 7626: 2019 is completely equivalent to ISO/IEC15416: 2016.

Vietnam Standard TCVN 7626: 2019 is compiled by the Standard technical subcommittee on TCVN/JTC1/SC31 "Automatic data capture", proposed by the Directorate for Standards, Metrology and Quality, and issued by the Ministry of Science and Technology.

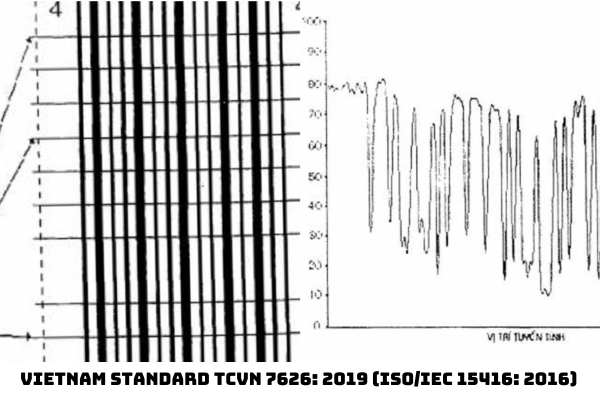

Barcode technology is based on the recognition of signs encoded in the form of bars and interspersed spaces of a defined size according to the principle of converting characters into signs called barcode specifications.

The barcode must be set up so that it can be reliably decoded when being used if it meets the basic purpose of being a machine-readable data carrier.

Therefore, manufacturers of barcode equipment and those who es/use barcodes request the publication and issuance of testing standards for objectively evaluating the quality of barcodes, as reference evidence when implementing equipment as well as applicable standards or to determine the quality of barcodes. These test specifications are the basis for the use of measuring equipment for process control and quality assurance during the establishment/fabrication/production of barcodes as well as their subsequent use.

The characteristics of barcode testing equipment are specified in ISO/IEC 15426-1.

Vietnam Standard TCVN 7626: 2019 should be applied in conjunction with the technical regulation on barcodes to be tested, which provides details of the specific barcodes needed to apply them.

This method provides barcode manufacturers and merchants with a common standard measure for exchanging information about post-print barcode quality.

Scope of application of Vietnam Standard TCVN 7626: 2019

Vietnam Standard TCVN 7626: 2019 specifies 3 matters:

- Prescribing the methodology in the assessment of individual properties of barcodes;

- Prescribing methods for quantifying measurement results to give an overall assessment of the quality of barcodes;

- Providing information on the causes of possible deviations from optimal levels, to assist users in applying appropriate correction measures.

This Vietnam Standard applies to barcode types for which its reference decoding algorithm has been specified, and barcodes read by linear scanning, but may be partially or fully applicable to other types of barcodes.

What are the abbreviated letters and symbols in Vietnam Standard TCVN 7626:2019?

Under the provisions of Section 4, Vietnam Standard TCVN 7626: 2019:

4.1 Abbreviations

EC: Edge contrast;

ECmin: Minimum value of EC;

ERN: Element reflectance non-uniformity;

ERNmax: Maximum value of ERN;

GT: Global threshold;

MOD: Modulation;

PCS: Print contrast signal;

RT: Reference threshold;

SC: Symbol contrast.

4.2 Symbols

A: The average width achieved by an element or combination of elements of a particular form;

C: Error correction constant;

e: The width of the narrow line of greatest width;

E: The width of the wide line of the smallest width;

ei: The size from the i-th edge to the analog edge, adjective from the dominant edge of the barcode;

F: Factors used to weaken the effect on disability levels achieved from minor changes; between the top and the depression zone within one element;

K: The minimum value of the absolute difference between the measured value and the reference value threshold;

k: Number of pairs of elements in a type barcode character (n, k);

M: The width of the element with the greatest deviation from A;

m: Number of modules in a barcode character;

N: The average value achieved by the wide/narrow ratio;

n: Number of modules in a type barcode character (n, k);

Rb: Reflectance coefficient of the bar;

RD: Reflectance coefficient of dark line;

RL: Reflectance coefficient of light line;

Rmax: Maximum reflectivity;

Rmin: Minimum reflectance coefficient;

Rs: Reflectance coefficient of blanks

RTj: The reference threshold between the width of module j and (j+1);

S: The total width of a character;

V: Decoding value;

VC: The decoding value of a barcode character;

Z: The average achieved size of the narrow line or modular size, as measured.

Thus, when viewing Vietnam Standard TCVN 7626: 2019, it is necessary to note the above-abbreviated letters and symbols for convenient viewing of this Vietnam Standard.

What are the general requirements for the measurement method according to Vietnam Standard TCVN 7626:2019?

Under subsection 5.1 of Vietnam Standard TCVN 7626: 2019, the general requirements for the measurement method according to Vietnam Standard TCVN 7626: 2019 are as follows:

- The measurement method specified in this Vietnam Standard is established to achieve maximum consistency of reflection coefficient measurements and measurements of bar widths and gaps of barcodes on different types of backgrounds. This method also considers similarity to conditions encountered in barcode scanning equipment.

- Measurements shall be made with a light source (such as a single wavelength of light) and a uniform pore diameter according to the application specification or determined by 5.2.1 and 5.2.2. A circular measuring hole is determined by its diameter according to Table 1. Application specifications may define other measuring hole diameters or shapes.

- When possible, barcode measurement should be done on the final copy, i.e. the printout for scanning. If this is not possible, see Appendix C for the method used to measure the reflection coefficient on a non-blurred background.

- The sampling method must be based on the number of statistically valid samples in the test batch. A minimum acceptance level must be established before conducting a barcode quality check. If the sampling plan has not been established in the formal quality assurance process or as agreed between the two parties, an appropriate sampling plan may be made based on ISO 2859-1.

LawNet