Vietnam: What are the technical requirements for concrete and reinforced concrete materials meeting corrosion resistance in the marine environment under National Standard TCVN 9346: 2012?

- What are the technical requirements for concrete and reinforced concrete materials meeting corrosion resistance in the marine environment in Vietnam under National Standard TCVN 9346: 2012?

- What are the design requirements for concrete and reinforced concrete materials meeting corrosion resistance in the marine environment in Vietnam?

- What are the requirements for concrete construction in Vietnam under National Standard TCVN 9346: 2012?

What are the technical requirements for concrete and reinforced concrete materials meeting corrosion resistance in the marine environment in Vietnam under National Standard TCVN 9346: 2012?

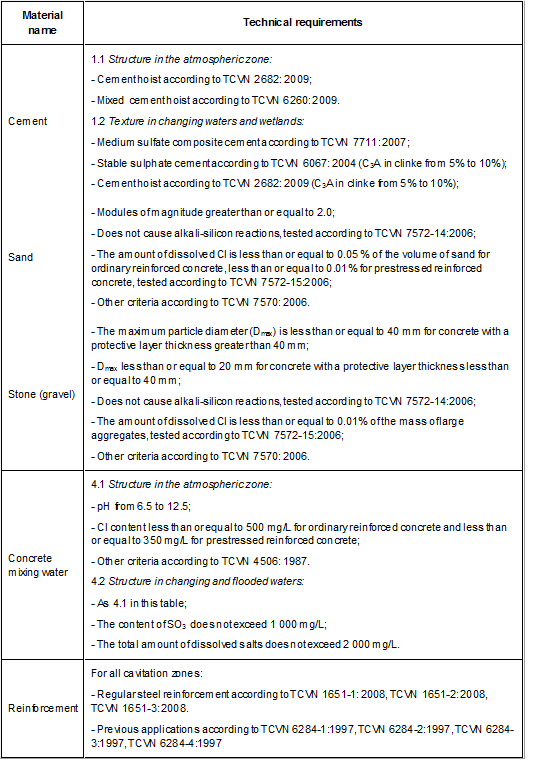

In Section 5, National Standard TCVN 9346: 2012, the technical requirements for concrete and reinforced concrete materials meeting corrosion resistance are specified as follows:

- Concrete and reinforced concrete materials must meet technical requirements according to the current National Standard and some additional requirements specified in Table 2.

- In order to ensure that concrete grades according to compressive strength and water repellency in Table 1 at the same time, concrete components should be designed and tested satisfactorily before use. In addition, the following technical requirements must be met:

+ The minimum cement content in 1 m3 of concrete in atmospheric and wetland areas is 350 kg/m3, and in changing waters is 400 kg/m3. The maximum cement content does not exceed 500 kg/m3.

+ Concrete mixture with low slump and not exceeding 8 cm. In case it is necessary to use a concrete mixture with a high slump to implement special construction technology (concrete pumping, pile filling...), it shall be used in combination with plasticizing or superplastic additives.

- For structures with shelf life requirements of more than 50 years (up to 100 years) located in flooded areas and water up and down, concrete needs to use normal sulfate durable cement or regular hoist cement combined with highly active mineral additives (silica fume, rice husk ash...).

What are the design requirements for concrete and reinforced concrete materials meeting corrosion resistance in the marine environment in Vietnam?

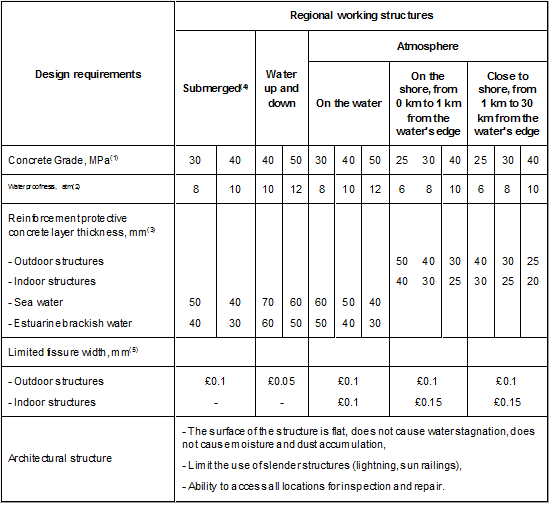

In Section 4, National Standard TCVN 9346: 2012, in addition to complying with current design standards: TCVN 5574: 1991, TCVN 4116: 1985, TCVN 2737: 1995, or other specialized normative standards, the structural calculation also must take additional corrosion prevention methods prescribed in accordance with 4.1, 4.2, 4.3, 4.4, 4.5 and 4.6.

- Minimum requirements for the concrete grade, waterproofing of concrete, thickness of the reinforced protective concrete layer, limited fissure width, and surface architectural structure of the building structure are specified in Table 1.

- Structures constructed by the underwater concrete pouring method (stuffed piles, foundation monuments) must increase by 20 mm of protection thickness compared to the minimum requirements stated in Table 1. Welded joints of closed piles need to be protected with 3 layers of hot bitumen grade III or IV.

- For structures that are difficult to construct the reinforcement protection layer thickness as required in Table 1, a smaller thickness can be used in combination with applying one of the following supporting protection measures:

+ Further protect the outer surface of the structure with a layer of dry sprayed concrete or a layer of waterproofing plastered mortar (or a combination of both layers) with a grade equivalent to the structural concrete grade and a thickness equal to the total thickness of the missing protective concrete.

+ Further protect the reinforcement with anti-corrosion coating, using corrosion inhibitors combined with waterproofing paint on the exterior of the structure, or by cathode method. These methods of protection are applied according to individual indications.

In no case shall the protective concrete layer thickness be less than 30 mm for surface structures facing sea vapor or seawater and less than 20 mm for structures located indoors.

- For prestressed cables placed in the structure, in addition to being protected by concrete as specified in Table 1, it is necessary to inject non-shrinkage and non-separating cement mortar with a minimum grade of 40 MPa into the cable conduit. Pre-stressed cables placed outside the structure are protected by oil in the cable conduit according to individual instructions.

- For structures in wetlands and rising and falling waters that require a shelf life of more than 50 years (up to 100 years), in addition to having to comply with the provisions of Table 1, one of the supporting protection measures must be applied at least as follows:

+ Increase concrete grade by 10 MPa, increase waterproofing by one level (2 atmospheres), and increase the thickness of the protective concrete layer by 20 mm compared to those specified in Table 1.

+ Enhance the protection of the outer surface of the structure with a layer of dry spray concrete with a grade of structural concrete with a thickness of 30 mm or a layer of dry spray concrete with a grade higher than structural concrete of 10 MPa with a minimum thickness of 20 mm.

+ Enhance direct protection of reinforcement by cathode method (according to separate indications).

- For structures in the above-water, onshore, and nearshore atmospheres requiring a shelf life of more than 50 years (up to 100 years), in addition to having to comply with the provisions of Table 1, one of the following supporting protection measures must also be applied:

+ Increase concrete grade by 10 MPa and waterproofing by one level or increase the thickness of the protective concrete layer by 20 mm.

+ Enhance the protection of the outer surface of the structure with a layer of dry-sprayed concrete with a grade of structural concrete with a minimum thickness of 15 mm.

+ Strengthen the anti-corrosion paint layer to cover the reinforcement surface before pouring concrete (materials and procedures for coating reinforcement according to separate regulations).

+ Sweep paint to waterproof structural surfaces, using reinforcement corrosion inhibitors or directly protecting steel reinforcement by cathodic protection method according to EN 12696: 2000.

What are the requirements for concrete construction in Vietnam under National Standard TCVN 9346: 2012?

In subsection 6.2, Section 6, National Standard TCVN 9346: 2012, the requirements for concrete construction in Vietnam are specified as follows:

Strictly comply with construction regulations according to TCVN 4453: 1995, in addition, must comply with the following requirements:

- Cement, sand, and stones need to be batched and stored to avoid the direct impact of seawater. If the aggregate is transported by sea or stored on the coast for a long time, before mixing concrete, the Cl- content of the aggregate must be checked as required in Table 2. When changing the source of aggregate extraction, it is necessary to re-check the indicators specified in Table 2.

- The production of concrete used for works in marine areas is prescribed as follows:

+ In case concrete is manufactured and constructed by fully mechanized (mixing at stations, transporting by pumps or specialized vehicles, pouring and compacting concrete mixture by machine): Concrete at the batching plant must have a slump suitable to construction conditions and the minimum strength must not be less than 1.15 times the concrete grade value specified in Table 1.

+ In case concrete is produced and constructed manually combined with mechanization (weighing, transporting, and pouring manually, mixing and compacting by machine): concrete at the batching plant must have a slump suitable to construction conditions and the minimum strength must not be less than 1.25 times the concrete grade value specified in Table 1.

- In the construction organization plan, it is necessary to take into account power outages, rain, heat, equipment malfunctions ... to take measures to shield the reinforcement and ensure the quality of concrete.

- Concrete is considered to be constructed satisfactorily for corrosion protection only when the criteria determined on the casting sample groups at the site and the actual protective concrete layer thickness satisfies the requirements specified in Table 1.

- The location of the circuit stopped construction applied according to TCVN 4453: 1995. To ensure the tightness of concrete at the stop circuit, it is necessary to perform the following works:

+ Brush and rinse the old concrete surface with fresh water.

+ Pour a layer of cement-sand mortar (the ratio is like the mortar of concrete) from 20 mm to 30 mm thick, compacted thoroughly then apply a new layer of concrete.

+ For stop circuits or water barrier expansion joints, water insulation tapes are made from non-rusty materials such as rubber, copper, stainless steel ...

- For reinforced concrete structures to be applied on-site in up and down waters, it is necessary to take shielding measures so that the surface of the structure is not soaked with seawater within the first 3 days. In case this is not possible, it is necessary to calculate the time for pouring concrete so that the concrete pouring work is completed at least 6 hours before the high tide floods the structure. In addition, in this case, it is necessary to apply measures to seal the formwork (nylon lining), not allow water to decay the concrete, and strengthen the protection of the reinforcement by coating the reinforcement before pouring concrete.

- Concrete maintenance is carried out according to TCVN 5592: 1991. Do not use seawater or brackish water for reinforced concrete maintenance.

- Pour concrete into seawater or brackish water follows the process of pouring concrete in water.

LawNet